Revolutionizing Hydrogen Production Through Seawater Electrolysis

The quest for sustainable energy sources has led researchers to explore innovative methods for hydrogen production, with seawater electrolysis emerging as a promising solution. However, challenges such as anode corrosion, unwanted reactions, and expensive catalysts have hindered the widespread adoption of this technology.

To tackle these obstacles, a team of scientists led by Prof. Hong Chen, Prof. Bing-Jie Ni, and Prof. Zongping Shao devised a groundbreaking approach to enhance the stability and efficiency of seawater electrolysis. Their research, published in the prestigious journal Science Bulletin, introduces a novel electrode design that revolutionizes the process of hydrogen generation from seawater.

The Power of Self-Supported Nickel-Iron Materials

Nickel-iron (NiFe) materials have emerged as key players in the realm of electrocatalysis due to their remarkable bifunctional properties for both hydrogen evolution and oxygen evolution. These self-supported materials offer high intrinsic activity and cost-effectiveness, making them attractive candidates for sustainable energy production.

Moreover, the integration of wood-based carbon (WC) structures as a substrate for NiFe catalysts has garnered significant attention. The hierarchical porous nature and excellent conductivity of WC make it an ideal host for active materials, enhancing the overall performance of the electrodes in seawater electrolysis.

Enhancing Stability with Tungsten-Doped NiFe Electrodes

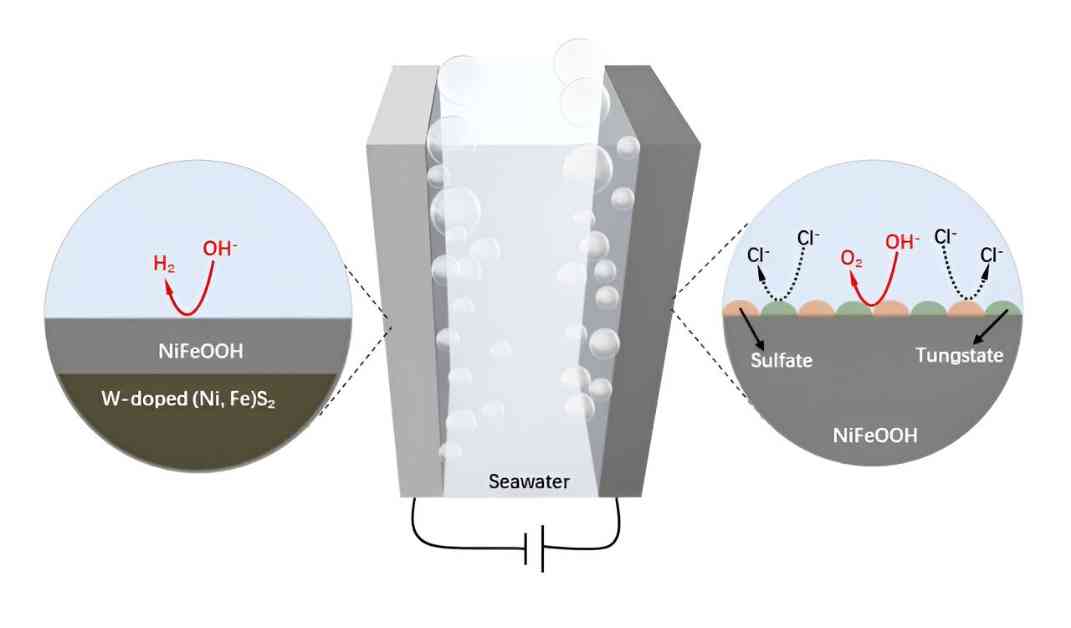

In their quest to improve the stability of NiFe-based electrodes in seawater electrolysis, the research team introduced tungsten into the catalyst design. By developing a specialized electrode composed of tungsten-doped NiFe sulfide supported on wood-based carbon (W-NiFeS/WC), they achieved remarkable advancements in anti-corrosion properties and overall performance.

The innovative electrode features a three-dimensional hierarchical porous structure with oriented microchannels, densely anchored nanoparticles, and high porosity. These structural characteristics enhance electrical conductivity, efficiency, and stability in alkaline seawater conditions, paving the way for efficient hydrogen generation.

Unveiling the Mechanisms of Efficient Seawater Electrolysis

The key to the superior performance of the W-NiFeS/WC electrode lies in its unique structure evolution during the oxygen evolution reaction (OER). This process generates anti-corrosive tungstate and sulfate species on the surface of active Ni/Fe oxyhydroxides, enhancing the durability and longevity of the electrode.

Additionally, the electrode’s self-evolved W-NiFeS decoration on NiFeOOH promotes efficient hydrogen evolution, further boosting the overall performance of the electrolysis process. These intricate mechanisms highlight the importance of structural design and material composition in advancing sustainable hydrogen production from seawater.

By combining the benefits of tungsten doping, wood-based carbon support, and NiFe catalysts, the researchers have unlocked new possibilities for efficient and cost-effective seawater electrolysis. The electrode’s low fabrication cost and high effectiveness make it a compelling choice for industrial-scale hydrogen production, marking a significant step towards a greener and more sustainable future.

Driving Innovation in Energy Conversion and Waste Utilization

Beyond its immediate impact on hydrogen production, this research underscores the broader implications of structure reconstruction for energy conversion reactions. The utilization of wood waste-derived carbon structures as efficient catalysts not only enhances the performance of electrochemical devices but also promotes a circular economy approach to waste management.

By repurposing abundant wood waste into valuable catalysts for seawater electrolysis, the researchers are setting a precedent for sustainable green hydrogen production. This holistic approach minimizes waste generation, reduces environmental impact, and contributes to the global transition towards clean and renewable energy sources.

In conclusion, the innovative seawater electrolysis technology developed by Prof. Hong Chen, Prof. Bing-Jie Ni, Prof. Zongping Shao, and their team represents a significant milestone in the quest for sustainable hydrogen production. Through the synergistic combination of advanced materials, unique electrode designs, and efficient catalysts, they have paved the way for a brighter and more sustainable future powered by green hydrogen.